Overall views

About Adhesive Labels

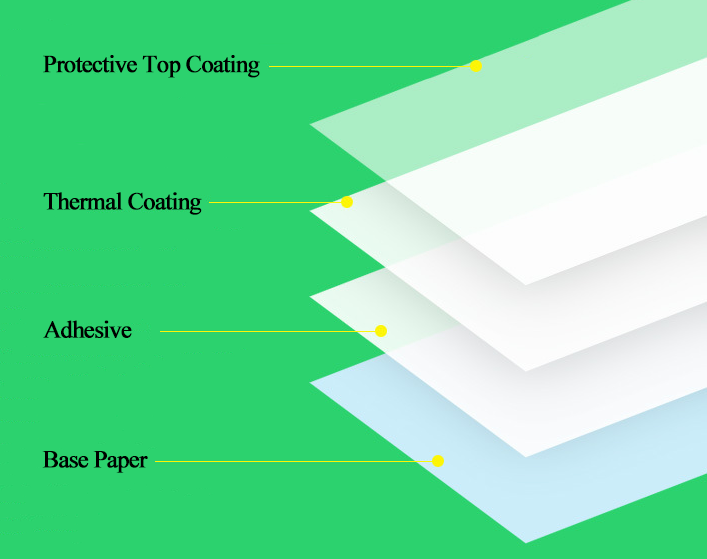

An adhesive label is a type of label with a pressure-sensitive adhesive backing that allows it to stick to surfaces, adhesive labels are more than just stickers on a product—they are a key part of product presentation, containing vital information, branding elements, and handling instructions. These labels play a role in helping products stand out on shelves, convey a brand’s message, and meet regulatory standards. This feature makes it ideal for numerous applications, from product branding to safety instructions. Here’s a breakdown of the key components.

Base Paper: This is the foundational layer made from high-quality paper or wood pulp. The base paper layer gives support and stability to the thermal paper, ensuring durability and resilience during printing.

Adhesive: This layer is applied to the top of the base layer. The adhesive is responsible for sticking under various conditions. Adhesives are generally grouped in three chemical categories: rubber, acrylic, and silicone. They also come in permanent and removable designs.

Thermal Coating: The thermal coating is the vital component that reacts to heat. It consists of dye, which is responsible for the colour, and developers like BPA and BPS. When exposed to heat, these components undergo a chemical reaction, producing the darkened areas that form text and images on the receipt.

Protective Top Coating: This protective layer shields the printed image from external elements such as light, water, oils, and scratches, thereby extending the longevity of the printed receipts.

Types of Adhesive Labels

Self-Adhesive Labels

Self-adhesive labels are a subset of pressure-sensitive labels. Unlike traditional labels requiring water or heat activation, these labels are ready to apply directly. This makes them ideal for high-speed production lines, where quick and efficient label application is necessary.

Pressure-Sensitive Labels

Pressure-sensitive labels stick to surfaces when light pressure is applied. They are suitable for a wide range of applications, from packaging to industrial equipment labels, due to their versatility and ease of application. Pressure-sensitive labels are commonly used in the food and personal care sectors.

Removable vs. Permanent Adhesive Labels

Removable adhesive labels are designed to peel off without leaving residue, making them perfect for temporary applications, such as pricing or promotional labels. Permanent adhesive labels, however, are more durable and are intended for long-term applications, such as labeling containers or machinery.

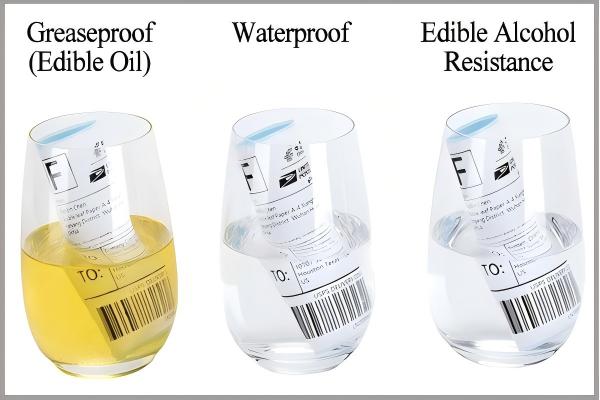

Specialty Adhesive Labels

Specialty adhesive labels are engineered for specific environments. For example, waterproof adhesive labels are used in environments with high moisture, and temperature-resistant labels are essential for products that will be exposed to extreme heat or cold. These specialty options provide reliable performance in unique conditions.

Label Adhesive Types

Hot Melt Adhesives: Known for their strong bonding ability, hot melt adhesives are ideal for packaging and product labeling applications requiring quick adhesion. They work well in moderate environments and offer excellent initial tack.

Acrylic Adhesives: Acrylic adhesives are known for their durability and are resistant to extreme temperatures. They are widely used for industrial applications where labels must withstand challenging environments.

Rubber-Based Adhesives: These adhesives provide a strong bond on difficult surfaces, making them suitable for applications that need a quick, reliable adhesion. However, they may lack the durability required for long-term applications.